Introduction

Organizations across FMCG, pharmaceuticals, food manufacturing, packaging and allied sectors are operating in a highly competitive and tightly regulated environment. Global markets demand consistency, safety, traceability and sustainable practices at every step of the value chain. This has made ISO standards one of the strongest tools for achieving operational excellence, risk reduction and international recognition.

Implementing ISO standards is no longer a certification exercise. It is a strategic approach that enhances product quality, protects brand integrity and builds long term customer trust. For companies aiming to expand globally or strengthen domestic operations, ISO frameworks set the foundation for structured growth.

Emaza Services Pvt. Ltd. supports businesses across industries with complete ISO implementation through audits, compliance assistance, documentation, gap assessment, training, integrated management system design and audit readiness support. With a presence in more than twenty countries and expertise in over six hundred projects, the organisation brings deep technical and practical experience to every implementation journey.

This guide explores how ISO standards transform businesses and how organisations can adopt them in a systematic and future ready manner.

Understanding ISO Standards and Their Importance

ISO is the International Organization for Standardization. It provides globally accepted frameworks that ensure consistency, safety, quality, sustainability and operational control. While each standard focuses on a specific domain, all ISO frameworks share a common objective which is to strengthen systems and create predictable outcomes.

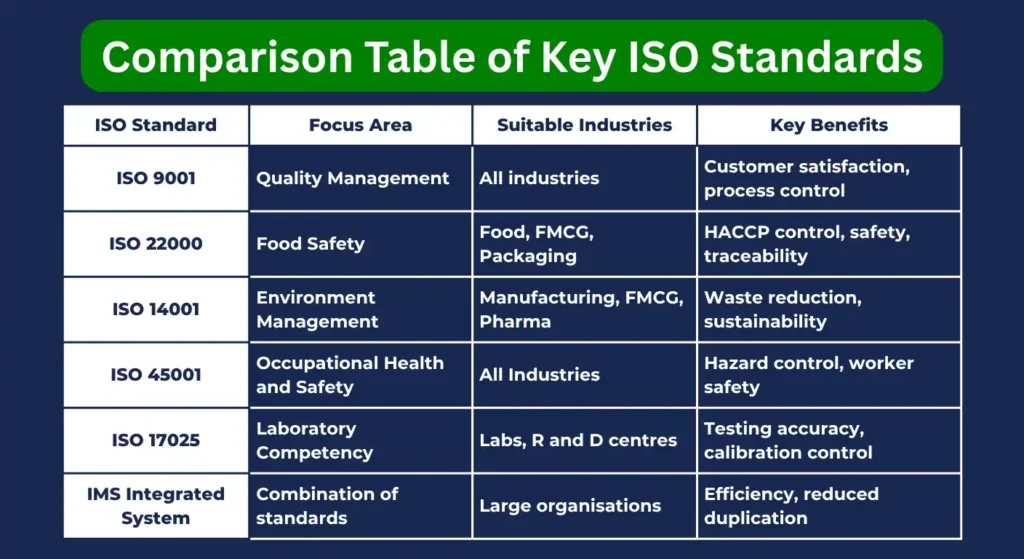

Key ISO standards relevant to FMCG, food, pharma and packaging

- ISO 9001 Quality Management

- ISO 22000 Food Safety Management

- ISO 14001 Environmental Management

- ISO 45001 Occupational Health and Safety

- ISO 17025 Laboratory Competence

- ISO 50001 Energy Management

- Integrated Management System IMS combining multiple standards

Every industry has unique requirements, but the core benefit remains the same. ISO helps organisations create systems that reduce errors, improve traceability, ensure compliance and deliver consistent results.

Why ISO Standards Matter in Modern Manufacturing

Enhancing operational efficiency

ISO creates structured processes. This reduces repetitive errors and helps teams work with clarity and responsibility.

Strengthening product and process consistency

Customers expect uniformity. ISO ensures every batch, process and output follows the same validated pathway.

Improving compliance

FSSAI norms, global export regulations, safety expectations and environmental controls all align with ISO requirements.

Boosting market competitiveness

ISO certified businesses enjoy higher trust from consumers, suppliers and regulatory bodies.

Enabling export growth

Countries and global brands often require ISO 9001, ISO 22000 or BRCGS equivalent systems before accepting products.

Building sustainability

ISO 14001 and ISO 50001 help companies reduce waste, optimise energy use and adopt environmentally responsible practices.

Step by Step Process of ISO Standards Implementation

Implementing ISO requires a structured roadmap. Although the timeline varies depending on the organisation’s size and complexity, the overall approach follows a logical sequence.

Step 1: Initial Interaction and System Review

Emaza begins with an on site visit or virtual review to understand current processes, organisational structure, existing documentation, compliance status and operational challenges.

Step 2: Gap Assessment

This identifies what is present, what is missing and what needs improvement. A detailed gap checklist is prepared covering documentation, processes, records, risk controls, monitoring and team responsibilities.

Example elements in a gap assessment checklist

• Standard operating procedures

• Process mapping

• Competency records

• Calibration and maintenance plans

• Internal audit structure

• Supplier evaluation

• Corrective action plans

• Hazard analysis for food safety

• Environmental impacts

• Safety risks and controls

Step 3: Documentation Development

ISO implementation requires structured documentation that is aligned with the organisation’s actual operations. Emaza supports companies in preparing manuals, SOPs, forms, templates and process controls that meet international expectations.

Step 4: Training and Awareness

Teams must understand why ISO is being implemented, how it works and their role in the system. Training covers requirements of the standard, documentation structure, roles, responsibilities and process controls.

Step 5: Process Implementation

This phase involves putting the documented processes into action. Teams record data, follow SOPs, conduct monitoring and perform verifications.

Step 6: Internal Audit

Internal audits detect gaps before the certification body visits. Emaza conducts mock audits, prepares corrective actions and ensures the system is ready.

Step 7: Management Review

Leadership evaluates the effectiveness of the system, identifies improvements and ensures alignment with business objectives.

Step 8: Certification Body Audit

Once the system is mature, the organisation undergoes Stage One and Stage Two audits conducted by an accredited certification body.

Step 9: Continuous Improvement

ISO is a continual process. Emaza supports clients with surveillance audits, corrective actions, periodic training and system upgrades.

Common Challenges During ISO Implementation and How to Overcome Them

Even established companies face hurdles during ISO adoption. Some of the most frequent challenges include:

1. Lack of clarity in documentation

Many companies work with old or disconnected documents. Emaza solves this by creating structured, user friendly and process oriented documents.

2. Resistance to change

Teams may struggle to adopt new processes. Regular training and communication help build acceptance.

3. Incomplete data and records

ISO relies on evidence based operations. Emaza guides teams in systematic record keeping.

4. Multiple departments working in silos

Integrating processes through IMS improves communication and consistency.

5. Misalignment between actual practices and documented processes

Implementation audits ensure real operations match documentation.

6. Limited audit readiness

Mock audits reveal gaps early and increase confidence during certification audits.

Case Style Example of ISO Implementation by Emaza Services

A leading pharmaceutical company had inconsistencies across its multiple manufacturing units. Documentation was scattered, compliance was inconsistent and data management lacked structure.

Challenges

• Fragmented systems

• Manual errors

• Limited audit readiness

Approach by Emaza

Complete system review

• Gap assessment

• Phase wise implementation

• Centralised documentation

• Internal audits

• Management review support

Results

• Strong regulatory compliance

• Improved audit readiness

• Smooth interdepartmental communication

• Unified integrated management system

The structured approach allowed the organisation to align all units under a common system and achieve certification with confidence.

How ISO Integrated Management Systems Boost Efficiency

Many organisations implement multiple ISO standards. When managed separately, they create duplication in documentation, audits and resources. IMS combines these into one unified system.

Key advantages

- One documentation system

- Common audit cycle

- Shared risk based approach

- Streamlined communication

- Higher operational clarity

- Fewer non conformities

Emaza specialises in designing IMS models that combine ISO 9001, ISO 14001, ISO 22000 and ISO 45001 for organisations seeking a single, smooth system.

Future Trends in ISO Implementation

The global manufacturing landscape is shifting rapidly. ISO standards are evolving to match modern requirements.

Key trends

- Greater focus on data security and digital traceability

- Increasing demand for sustainability and carbon reporting

- Integration of artificial intelligence driven monitoring

- Rising global alignment of food safety norms

- Climate impact and circular economy principles

Organisations that adopt strong ISO systems now will be more competitive and future ready.

Conclusion

ISO standards have become essential for companies that aim to build strong processes, ensure quality, enhance safety and grow globally. Whether it is ISO 9001 for quality, ISO 22000 for food safety, ISO 14001 for sustainability or an integrated system that connects all requirements, the right implementation approach determines long term success.

Emaza Services Pvt. Ltd. provides end to end ISO implementation support including gap assessments, audits, documentation, training, corrective actions and certification readiness. With expertise across FMCG, food, pharma, packaging, laboratories and export oriented businesses, Emaza enables organisations to achieve global standards with confidence and clarity.

Call to Action

To implement ISO standards smoothly and strengthen your organisation’s compliance, quality and operational excellence, connect with our expert team.

Emaza offers personalised consulting, structured audits, documentation assistance and training programs designed for modern industries.

If you would like to explore ISO implementation, book a consultation or register for upcoming training sessions. Let us help you build a stronger, safer and globally recognised operation.