Introduction

The global food industry is under unprecedented pressure to reduce waste, conserve resources and operate in a sustainable, responsible manner. Rising consumer awareness, strengthened environmental regulations, increasing production costs and climate change expectations have made waste reduction a strategic priority for food and FMCG businesses.

Food processing generates waste at every stage including raw material handling, peeling and sorting, trimming, cooking, packaging, storage, transportation and consumer use. According to global estimates, nearly one third of all food produced is lost or wasted. This represents enormous financial loss, environmental impact and social inefficiency.

The circular economy model is transforming how food businesses approach waste. Instead of the traditional linear take make dispose model, the circular economy promotes resource efficiency, reuse, recycling, regenerative practices and waste prevention. It aligns directly with sustainability frameworks such as EcoVadis, SEDEX SMETA and QIMA, which expect companies to integrate responsible environmental practices into their operations.

Emaza Services Pvt. Ltd. supports organisations across food processing, FMCG, packaging, agriculture and allied industries in implementing circular economy principles, waste reduction strategies, environmental monitoring, sustainability scoring and responsible resource management. With experience across food safety, quality systems and sustainability frameworks, Emaza helps businesses build efficient, compliant and environmentally responsible operations.

This guide explores how circular economy principles can be applied in food processing, how waste can be minimised at each stage and how companies can implement these models effectively.

Understanding the Circular Economy in Food Processing

The circular economy is based on the idea of designing systems that eliminate waste and keep materials in use for as long as possible. For food processing, this means maximising resource efficiency, preventing losses, repurposing by products and creating value from materials that would otherwise be discarded.

Key Principles

• Waste prevention

• Resource optimisation

• Regeneration of biological materials

• Reuse and recycling

• Sustainable production and consumption

• Responsible sourcing

• Energy efficiency

• Closed loop systems

Food processing companies are adopting circular economy models to reduce waste, improve profitability, strengthen sustainability scores and meet global buyer expectations.

Types of Waste in Food Processing

Understanding the types of waste helps organisations design effective reduction strategies.

1. Raw Material Waste

• Peels

• Seeds

• Trimmed parts

• By products of cutting, sorting and grading

2. Processing Waste

• Overcooked batches

• Excess water usage

• Oil residues

• Thermal energy loss

• Spillage during mixing or filling

3. Packaging Waste

• Plastic wrappers

• Cardboard boxes

• Laminates

• Non recyclable packaging

4. Storage and Transportation Waste

• Temperature abuse

• Spoilage due to poor handling

• Improper stacking

• Pest related losses

5. Post Consumer Waste

• Excess packaging

• Limited recycling practices

• Consumer level food discard

Circular economy strategies aim to reduce waste across all categories.

Why Circular Economy Is Essential for Modern Food and FMCG Businesses

1. Cost Optimisation

Waste reduction directly reduces production costs.

2. Environmental Performance

Better waste management improves sustainability scores under EcoVadis, SMETA and QIMA.

3. Resource Conservation

Efficient use of water, energy and raw material improves long term viability.

4. Compliance with Environmental Regulations

Authorities expect responsible waste handling and sustainable manufacturing.

5. Global Buyer Requirements

International retailers demand responsible sourcing and environmental performance from suppliers.

6. Improved Brand Perception

Consumers prefer environmentally responsible brands.

7. Stronger Operational Efficiency

Streamlined processes reduce downtime and batch rejections.

Circular economy practices create long term resilience for businesses.

Circular Economy Framework for Food Processing

A Step by Step Model

Emaza uses a structured circular economy model to help organisations adopt sustainable practices.

Step 1: Waste Mapping and Resource Flow Analysis

• Identify waste hotspots

• Analyse material flow

• Study energy and water use patterns

• Assess packaging consumption

• Review by product generation

Step 2: Root Cause Analysis

• Process inefficiencies

• Equipment limitations

• Poor storage practices

• Weak supplier quality

• Inadequate handling

• Packaging design issues

Step 3: Process Optimisation

• Redesign of workflows

• Improved storage systems

• Advanced processing technologies

• Better layout planning

Step 4: Waste Valorisation

• Converting waste into new products

• Using by products as raw material

• Composting organic matter

• Recycling packaging materials

Step 5: Sustainable Sourcing

• Preferred suppliers

• Lower carbon raw materials

• Ethical sourcing supported by SEDEX and QIMA

Step 6: Packaging Redesign

• Reduced material packaging

• Recyclable materials

• Compostable packaging

• Lighter weight formats

Step 7: Monitoring and Continuous Improvement

• Waste dashboards

• Environmental KPIs

• Audit programs

• EcoVadis documentation

• Worker awareness

This structured model helps organisations develop long term sustainable operations.

Circular Economy Opportunities Across Different Stages of Food Processing

1. Raw Material Handling

• Use trimming waste for animal feed

• Recover nutrients for biofertilizers

• Convert peels into functional ingredients

• Reduce peeling thickness through automation

2. Processing Stage

• Heat recovery from boilers

• Reuse of process water after treatment

• Oil filtration and reuse in controlled processes

• Lean manufacturing systems to reduce overproduction

3. Packaging

• Transition from multilayer plastics to recyclable materials

• Introduce refill, reuse and returnable packaging formats

• Optimise packaging weight to reduce material consumption

4. Storage and Distribution

• Better cold chain management

• Digital sensors for temperature monitoring

• Improved storage layouts

• Waste minimising route planning

5. Post Consumer Stage

• Encourage recycling programs

• Design packaging for ease of segregation

• Introduce awareness campaigns

Circular interventions vary depending on the product, process and facility type.

Circular Economy and Sustainability Frameworks

Circular economy practices directly influence sustainability scoring under global frameworks.

EcoVadis

• Strong scoring for environment

• Waste reduction performance

• Energy and water efficiency

• Packaging reduction initiatives

SEDEX SMETA

• Environmental pillar

• Resource management documentation

• Worker involvement in sustainable practices

QIMA

• Environmental compliance validation

• Waste handling verification

• Responsible sourcing programs

Businesses integrating circular practices experience improved sustainability performance across all frameworks.

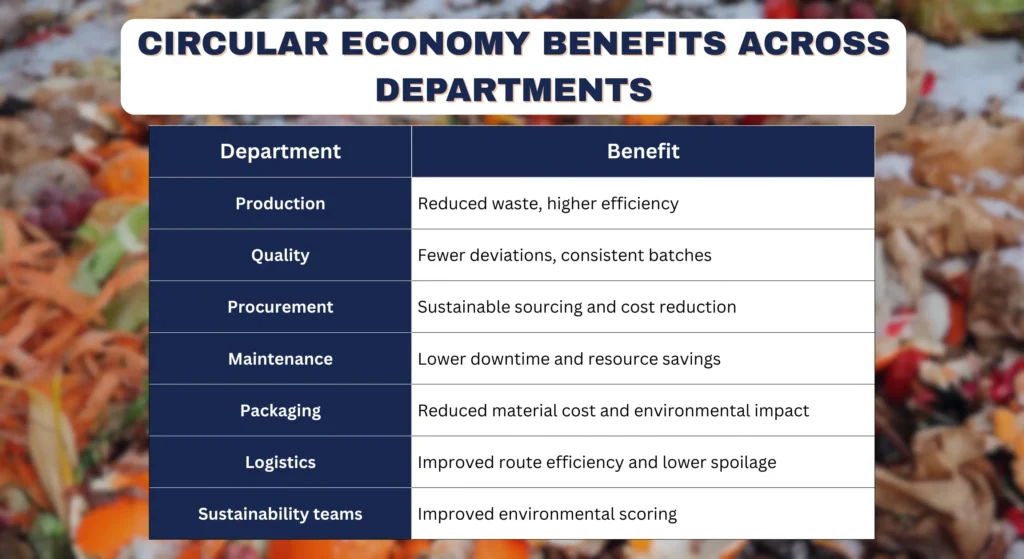

Table: Circular Economy Benefits Across Departments

| Department | Benefit |

| Production | Reduced waste, higher efficiency |

| Quality | Fewer deviations, consistent batches |

| Procurement | Sustainable sourcing and cost reduction |

| Maintenance | Lower downtime and resource savings |

| Packaging | Reduced material cost and environmental impact |

| Logistics | Improved route efficiency and lower spoilage |

| Sustainability teams | Improved environmental scoring |

Circular economy strengthens cross functional performance.

Practical Waste Reduction Strategies for Food Processing Units

Raw Material Optimisation

• Improve supplier grading standards

• Introduce precision cutting equipment

• Use all edible portions

Water Management

• Reuse water after filtration

• Adopt low water cleaning techniques

• Monitor and minimise process water use

Energy Efficiency

• Heat recovery systems

• Energy efficient boilers

• LED lighting

• Automatic power controls

Packaging Waste Reduction

• Remove unnecessary layers

• Use recycled content materials

• Shift to mono materials for easier recycling

Process Control

• Real time monitoring

• Automation

• Lean scheduling

• Preventive maintenance

Waste to Value

• Organic waste to compost

• By products to nutraceuticals

• Food grade waste to flavour extracts

These strategies build the foundation of resource efficient operations.

Case Study

A Large Snack Manufacturer Implements Circular Economy Practices

A snack manufacturer experienced high wastage in raw materials, energy and packaging. This increased production cost and affected sustainability scores required by buyers.

Challenges

• Over trimming of raw materials

• Excess fryer oil usage

• High packaging waste from mono use laminates

• Energy loss from outdated equipment

Emaza’s Approach

• Full waste mapping and circular assessment

• Upgraded cutting systems to reduce trimming waste

• Oil filtration system to extend oil life

• Packaging optimisation to reduce laminate usage

• Heat recovery installation in frying section

• Worker training program on waste reduction

Results

• Raw material wastage reduced by twenty five percent

• Energy usage reduced by fifteen percent

• Packaging material cost reduced

• Improved sustainability scoring under EcoVadis and QIMA

• Enhanced relationship with global buyers

Future Trends in Circular Economy for Food Processing

• Zero waste manufacturing models

• Usage of AI for predictive waste management

• Increased recyclable packaging adoption

• Digital environmental monitoring

• Carbon footprint reporting

• Biomass energy generation

• Sustainable procurement systems

Forward looking businesses are integrating these trends into long term strategies.

Conclusion

Circular economy is transforming the food and FMCG industries by reducing waste, improving resource efficiency, strengthening sustainability performance and meeting global buyer expectations. By adopting circular models, organisations can lower costs, enhance environmental responsibility and gain competitive advantage.

Emaza Services Pvt. Ltd. supports companies with complete circular economy integration including waste mapping, process optimisation, packaging redesign, environmental monitoring, sustainability scoring and responsible sourcing implementation. With expertise across food safety, sustainability and global compliance frameworks, Emaza helps organisations build operations that are efficient, compliant and future ready.