EU PPWR and India’s EPR Rules Are Redefining Packaging Responsibility

Introduction

Packaging is no longer just a functional or marketing element. It has become a regulatory, environmental, and reputational priority for companies operating in global and domestic markets. Governments are tightening packaging waste laws to reduce pollution, improve recyclability, and enforce producer accountability.

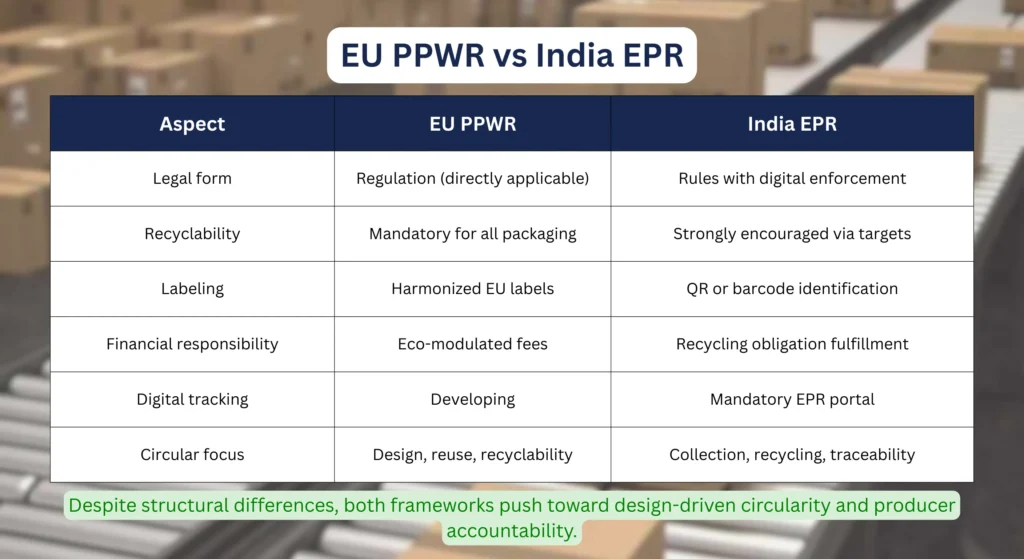

Two major regulatory developments are reshaping packaging compliance:

- The European Union Packaging and Packaging Waste Regulation (PPWR) is entering into force in 2025 and becoming effective by mid-2026

- India’s expanded Extended Producer Responsibility (EPR) framework under the Plastic Waste Management Amendment Rules, with stricter tracking and recycling obligations from July 2025

Together, these regulations signal a shift from voluntary sustainability efforts to mandatory circular economy compliance.

This article compares EU and Indian packaging regulations, explains what is changing, and outlines how companies can future-proof packaging design, reporting and compliance systems.

Why Packaging Compliance Is Under Global Scrutiny

Packaging waste is one of the fastest-growing environmental challenges worldwide. In response, regulators are moving toward:

- Mandatory recyclability

- Clear consumer labeling

- Financial responsibility for waste

- Digital tracking and traceability

- Measurable recycling outcomes

For producers, importers, and brand owners, this means packaging compliance is now a core business risk, not a secondary sustainability issue.

EU Packaging and Packaging Waste Regulation (PPWR)

The EU PPWR replaces the earlier Packaging and Packaging Waste Directive and creates a harmonized, directly applicable regulation across all EU member states.

Key Timeline

- Regulation enters into force in 2025

- Most obligations apply from mid-2026

- Progressive targets extend toward 2030 and beyond

Core Requirements Under EU PPWR

1. All Packaging Must Be Recyclable

By design and by practice, packaging placed on the EU market must be recyclable. This includes:

- Material compatibility

- Ease of sorting

- Availability of recycling infrastructure

Non-recyclable packaging will gradually be restricted or phased out.

Source

https://www.algoodbody.com/eu-packaging-and-packaging-waste-regulation-ppwr/

2. Mandatory Recycling Labels

Packaging must carry clear, harmonized labels indicating:

- Material type

- Recycling instructions

- Disposal guidance for consumers

This reduces confusion and improves recycling rates across EU markets.

3. Design for Reuse and Waste Reduction

The PPWR introduces reuse targets for specific packaging formats and emphasizes:

- Lightweighting

- Reduction of unnecessary packaging

- Refillable and reusable systems

Single-use and excessive packaging face increased scrutiny.

4. Eco-Modulated EPR Fees

Producers must finance the collection, sorting, and recycling of packaging waste. Crucially, fees will be eco-modulated, meaning:

- Better recyclability = lower fees

- Poor design = higher financial burden

This creates a direct economic incentive for circular packaging design.

India’s Extended Producer Responsibility (EPR) Framework

India has significantly expanded its Plastic Waste Management Rules to improve accountability and traceability across the packaging value chain.

Key Timeline

- Strengthened EPR rules already in effect

- New digital marking requirements from July 2025

- Recycling targets increase annually

Key Changes Under India’s EPR Rules

1. Mandatory Barcode or QR Code on Plastic Packaging

From July 2025, every plastic package must carry:

- Barcode or QR code

- Unique identification number

This enables digital tracking of packaging throughout its lifecycle.

2. Digital EPR Portal Reporting

Producers, importers, and brand owners must:

- Register on the CPCB EPR portal

- Report packaging quantities by category

- Submit evidence of recycling or end-of-life processing

Non-compliance can lead to penalties and operational restrictions.

3. Rising Recycling Targets

India has defined separate recycling targets for:

- Rigid plastics

- Flexible plastics

- Multilayer plastics

These targets increase every year, pushing companies toward better material choices and recycler partnerships.

4. Stronger Accountability Across the Value Chain

EPR responsibility applies to:

- Brand owners

- Importers

- Manufacturers

- Online sellers

Responsibility cannot be transferred without documented compliance.

What This Means for Businesses

Companies operating across regions must now manage multi-jurisdictional packaging compliance.

Key implications:

- Packaging design must consider recyclability from the start

- Digital traceability systems are no longer optional

- Sustainability claims must align with regulatory evidence

- Poor packaging design increases compliance costs

- Reporting accuracy is critical

Failing to adapt exposes businesses to fines, market access restrictions, and reputational damage.

How to Future-Proof Packaging Design and Compliance

1. Design for Circularity

- Shift to mono-materials where possible

- Avoid complex laminates

- Use recycled content responsibly

- Reduce packaging weight

2. Integrate Digital Traceability

- Implement QR or barcode systems early

- Align internal data with regulatory portals

- Track packaging flows across markets

3. Align Global Packaging Strategy

- Use EU PPWR as a design benchmark

- Adapt India EPR reporting at the country level

- Standardize internal packaging data systems

4. Strengthen Supplier and Recycler Engagement

- Evaluate the recyclability claims of suppliers

- Build partnerships with authorized recyclers

- Maintain audit-ready documentation

5. Link Packaging Compliance to Sustainability Ratings

- EcoVadis environmental scoring

- ESG and sustainability disclosures

- Buyer responsible sourcing programs

Well-designed packaging improves both compliance and brand value.

Circular Economy as a Business Advantage

Organizations that move early toward circular packaging benefit from:

- Lower long-term EPR costs

- Easier regulatory approvals

- Stronger buyer acceptance

- Improved sustainability ratings

- Reduced environmental footprint

Circular economy is no longer optional. It is a competitive differentiator.

Conclusion

The EU PPWR and India’s expanding EPR framework represent a decisive shift in how packaging is regulated. Both demand recyclable design, transparent labeling, digital traceability, and producer accountability.

Companies that align packaging design and compliance systems now will avoid future disruptions, control costs, and strengthen sustainability credibility across global markets.

Emaza Services Pvt. Ltd. supports organizations with packaging compliance assessments, EPR registration and reporting, circular packaging strategy, supplier audits, and sustainability integration, helping businesses navigate complex regulatory landscapes with confidence.